Pulleys and Mechanical Advantage Systems

Raising systems are essential in any rescue or rigging scenario in which loads are lifted using rope. A raising system using a combination of pulleys to leverage the force applied in lifting is referred to as a mechanical advantage (M/A) system. Whether building a simple or complex M/A system, it’s important to first understand how pulleys operate.

How Pulleys Work

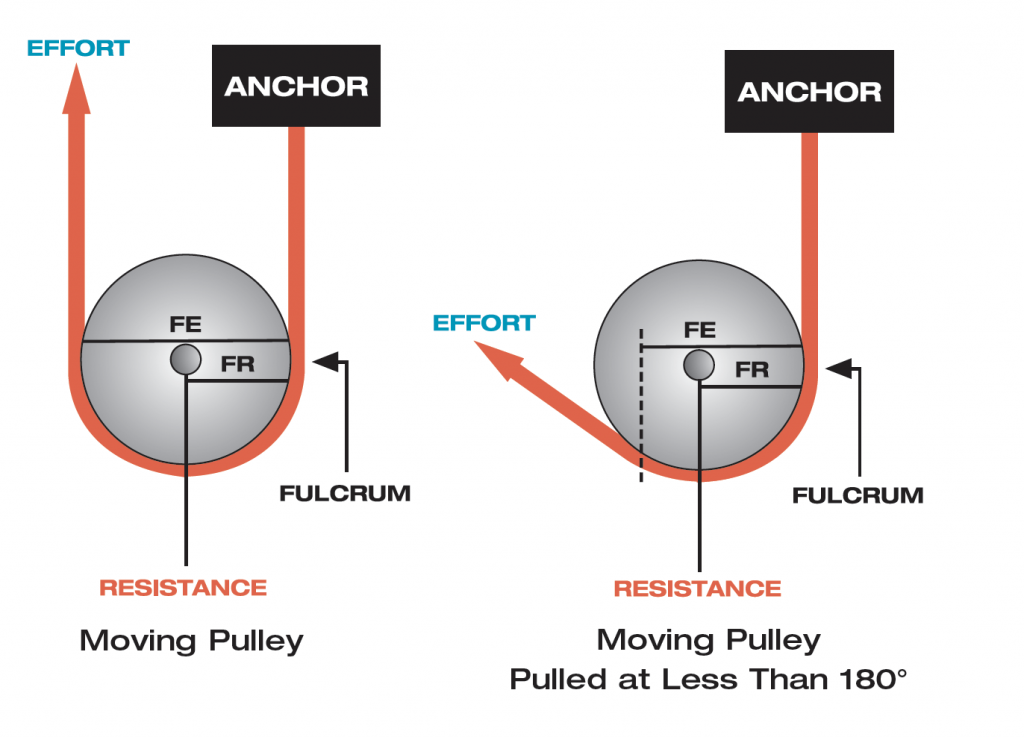

A fixed pulley can be looked at as a First Class Lever. The fulcrum is located at the pin in the center of the sheave, directly below the carabiner that anchors the pulley in place. Because the sheave is round, the distance from the pin (fulcrum) to the point the rope leaves the sheave and drops to the resistance (load) is equal to the distance from the pin to the point that the rope leaves the sheave and drops to the effort (force). The two lever arms are equal resulting in 1:1 mechanical advantage.

A moving pulley can be looked at as a Second Class Lever. The fulcrum is located on the edge of the sheave directly below the point the rope is attached to the anchor. One lever arm extends from the fulcrum to the pin which is directly above the carabiner that attaches the resistance (load) to the pulley. The other lever arm extends from the fulcrum to the point where the rope leaves the sheave and goes to the effort (force). This lever arm is twice as long as the other arm, resulting in 2:1 mechanical advantage.

Pulleys in Mechanical Advantage Systems

Pulleys perform two distinct functions in mechanical advantage systems. If the pulley is attached to the anchor, it is called a fixed or change of direction pulley. Its job is to change the direction of pull on the rope. If the pulley is attached to the load, it is a movable or mechanical advantage pulley. Its job is to increase the mechanical advantage of the system.

A ratchet is a device that, when attached to an anchor, will hold the rope so that the load will not lower back down when the pulling force is released. This acts as a safety so the load will not fall back down if the haul team lets go of the rope. This also allows us to reset the mechanical advantage pulleys so we can haul the load further. The number of times that a raising system will need to be reset will depend on the distance the load must be raised and the distance the raising system can be extended. An ascender or mechanical rope grab, or a friction knot tied with a prusik loop can be used as a ratchet.

By building systems using different combinations of mechanical advantage pulleys, change of direction pulleys, rope, anchors and ratchets, we can come up with the right tool for the specific job we need to accomplish. Generally, using the lowest mechanical advantage needed to get the job done will result in the quickest rescue because it requires fewer resets.

Simple Pulley Systems

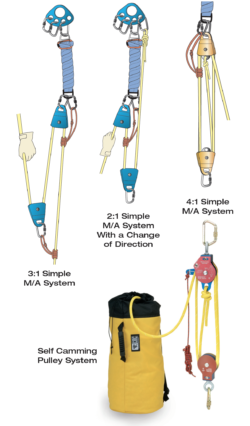

Simple M/A systems can be defined as systems with all the moving pulleys moving at the same speed as the load. A few simple pulley systems are most frequently used. The most common is a 3:1 mechanical advantage, sometimes called a “Z” rig because when rigged, the rope looks like a “Z”. In theory, a 100-pound pull would raise a 300-pound load. Due to friction, the actual mechanical advantage is slightly lower.

Many confined space operations require vertical entry. When we build a mechanical advantage system to move a load in this situation, a simple “Block and Tackle” system such as a 2:1 “Ladder Rig” or a 4:1 with double pulleys at the top and bottom can be used.

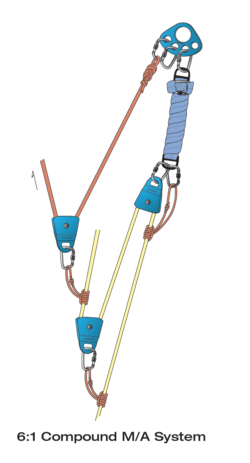

Compound Pulley Systems

Compound pulley systems are created when a simple pulley system is pulling on another simple pulley system. By adding a 2:1 mechanical advantage to a 3:1 mechanical advantage system you compound, or multiply, the mechanical advantage and end up with a 6:1. A 3:1 pulling on another 3:1 gives you a mechanical advantage of 9:1.

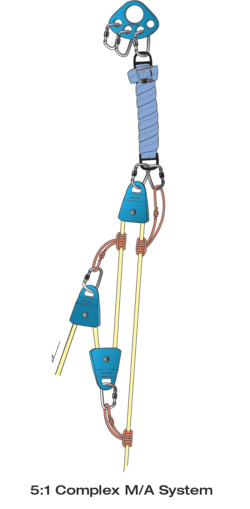

Complex Pulley Systems

A system that is neither simple or compound is a complex pulley system. The 5:1 shown is a complex system.

As the mechanical advantage increases, the amount of rope that must be pulled through the system also proportionally increases. With this in mind, it is best to use as little mechanical advantage as possible to complete the task. A simple 1:1 with a change of direction and a ratchet, with enough manpower to pull the load will usually get the job done quicker. When a manpower shortage becomes the problem, increase the mechanical advantage.

Piggyback Systems

Another method that can be used is to “piggyback” a mechanical advantage system on a haul line. The load is supported on a separate rope held by a ratchet, and a pre-rigged mechanical advantage system is connected to the haul line with a prusik hitch when the load needs to be raised. This can be helpful in situations where the load is raised and lowered back and forth a number of times. Piggyback systems can be of any level of mechanical advantage. While not common, piggyback lowering systems can also be rigged. They are usually used for short distances or when knot passing.

The “T” Method

Determining the mechanical advantage of pulley systems can be accomplished in a number of ways. Most are specific to one type of system. The “T” Method works for all systems and provides other important information such as the maximum force applied to each component of the system. It works by determining the units of tension on each segment of rope in the system. The actual value of 1 unit of tension varies as the actual input and output forces change. The minimum unit of tension is determined by the load being hauled and by the mechanical advantage of the system. The maximum unit of tension is determined by the maximum input force applied to the system. The input force is determined by the number of haulers on the haul team.

The basis of the “T” Method goes back to basic pulley theory. If there is 1 kN of force suspended on the end of the rope going through a pulley there must be 1 kN of force on the other end of the rope to hold it in equilibrium. 1 kN of force on each side puts 2 kN of force on the top of the pulley that is attached to the anchor (or to a prusik or ascender/rope grab that is connected to a segment of rope) within the pulley system. These units of tension are added to the units that are already on that segment. The sum of the units of tension at the output end is the mechanical advantage of the system.

To learn about more how to calculate mechanical advantage, you can refer directly to either the CMC Rope Rescue Manual or the CMC Confined Space Entry and Rescue Manual.

Got Something to Add?

Roger That wants to know about your pulley systems. Click “reply now” or send your answer to rogerthat@cmcrescue.com for a chance to be featured in his next post!